The Rise of Spray Foam Insulation in Metal Roofing

As an experienced roofing contractor, I’ve had the privilege of witnessing the remarkable evolution of roofing materials and techniques over the years. One innovation that has truly captivated me is the use of spray polyurethane foam (SPF) insulation in metal roofing systems. This revolutionary insulation solution has been reshaping the landscape of the roofing industry, offering a range of benefits that are simply too compelling to ignore.

Metal roofing has long been a favorite among homeowners and commercial building owners alike, prized for its exceptional durability, longevity, and aesthetic appeal. However, traditional insulation methods have often fallen short when it comes to effectively insulating metal roofs. This is where spray foam insulation steps in, providing a seamless and efficient solution that addresses the unique challenges of metal roofing.

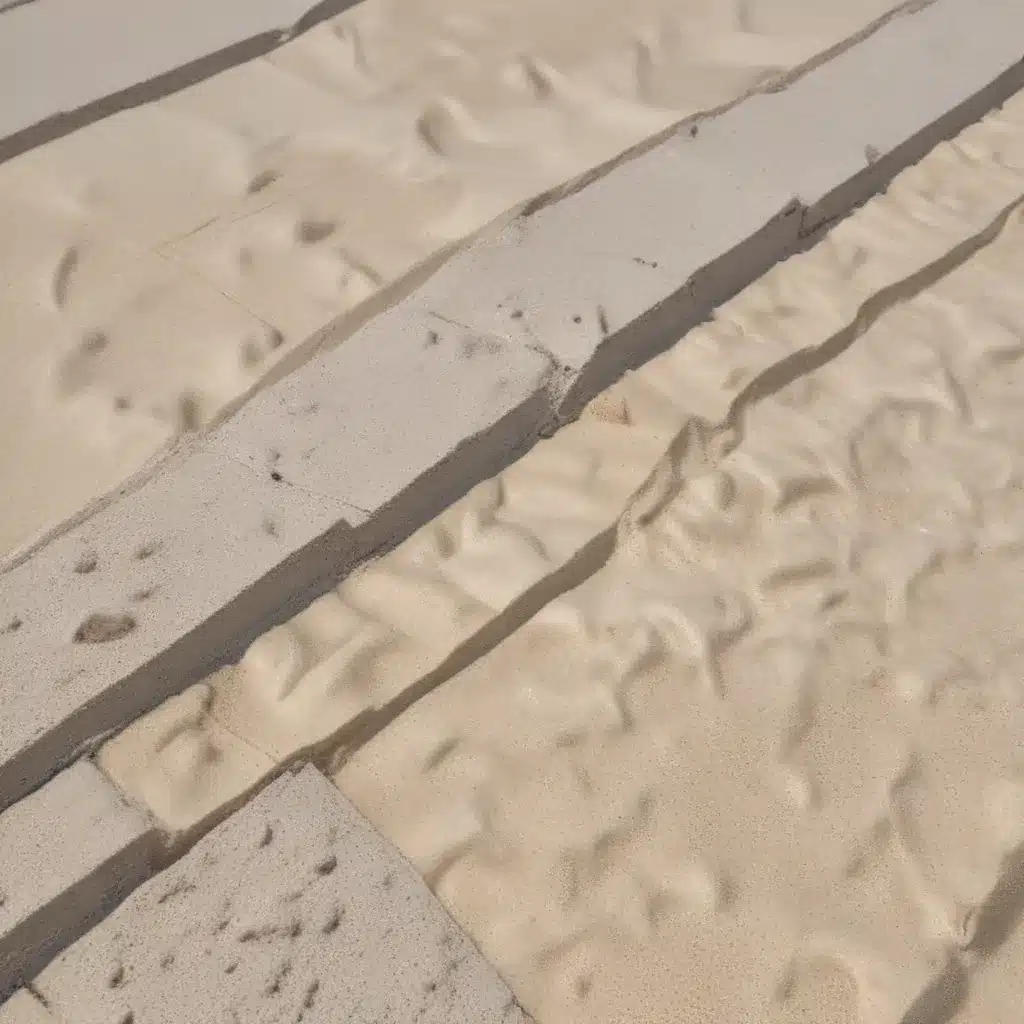

The airtight seal created by spray foam insulation sets it apart from other insulation materials. Unlike traditional methods like fiberglass batts or rigid boards, spray foam adheres directly to the metal surface, forming a continuous barrier that prevents air leakage and thermal bridging. This results in superior thermal insulation performance, helping to maintain consistent indoor temperatures and significantly reducing energy consumption for heating and cooling.

Unparalleled Insulation and Waterproofing Benefits

One of the standout features of spray foam insulation is its exceptional waterproofing capabilities. The seamless application creates a continuous barrier that protects the roof from leaks and water damage, safeguarding the integrity of the entire roofing system. This is particularly crucial in regions like the desert southwest, where sporadic rain and intense monsoon storms can pose a constant threat to the longevity of a roof.

Moreover, spray foam insulation’s superior thermal insulation properties make it an ideal choice for metal roofing applications in both hot and cold climates. In scorching desert environments, the insulation helps to minimize heat gain, reducing the strain on cooling systems and ensuring a more comfortable indoor environment. Conversely, in colder regions, the insulation prevents heat loss, providing enhanced energy efficiency and cost savings on heating expenses.

Enhancing Durability and Structural Integrity

Beyond its impressive insulation and waterproofing attributes, spray foam insulation also contributes to the overall durability and structural integrity of metal roofing systems. The foam’s adherence to the metal surface provides additional rigidity and strength, helping to safeguard the roof against the harsh weather conditions often encountered in the desert southwest.

Metal roofs are typically exposed to extreme temperatures, intense sunlight, and powerful winds – all of which can take a toll on the longevity of the roofing system. By applying spray foam insulation, the roof gains an extra layer of protection, shielding it from the ravages of the elements and extending its lifespan. This not only benefits the property owner’s investment but also contributes to a more sustainable built environment.

Quieter Indoor Environments and Pest Control

Another notable advantage of spray foam insulation for metal roofs is its ability to enhance indoor comfort and reduce noise transmission. The dense, insulating properties of the foam act as an effective sound barrier, dampening the impact of heavy rainfall, hail, or even strong winds. This results in a quieter and more peaceful indoor environment, which can be particularly valuable for both residential and commercial properties.

Furthermore, the airtight seal created by spray foam insulation helps to prevent the entry of pests and insects, ensuring a pest-free indoor environment. This not only enhances the overall hygiene and cleanliness of the building but also protects the integrity of the roofing system itself, as pest infestations can lead to costly damage over time.

Implementing Spray Foam Insulation: The Process

The process of applying spray foam insulation on metal roofs involves several crucial steps, each requiring the expertise of a skilled and experienced roofing contractor. Before the insulation is applied, the metal roof surface must be thoroughly cleaned and inspected for any existing damage or loose fasteners. This ensures a proper substrate for the application of the spray foam.

The type of spray foam insulation used – whether open-cell or closed-cell – is selected based on the specific needs of the metal roof and the desired level of insulation performance. Specialized equipment, including a spray gun and a foam application system, is utilized to ensure a seamless and uniform application.

It’s important to note that the initial installation costs of spray foam insulation may be higher than some traditional insulation materials. However, the long-term savings and reduced energy consumption that can be achieved with this solution often make it a worthwhile investment. By considering the return on investment (ROI) and the overall lifecycle cost of the roofing system, property owners can make an informed decision that aligns with their budgetary and energy-efficiency goals.

Spray Foam Insulation and Energy Efficiency

One of the most compelling aspects of spray foam insulation for metal roofs is its impact on energy efficiency. By creating a continuous, airtight barrier, spray foam insulation significantly reduces the amount of heat transfer through the roof, which in turn lowers the demand for heating and cooling.

According to the Department of Energy, spray foam insulation can reduce energy costs by up to 30% compared to traditional insulation methods. This translates to substantial long-term savings for homeowners and commercial building owners, making it a wise investment that pays dividends over time.

To illustrate the potential savings, let’s consider a few real-world examples:

A large commercial building in the Midwest installed spray foam insulation on its metal roof. The building was previously heated and cooled using a traditional HVAC system. After the installation, the building was able to reduce its energy consumption by 25%, resulting in significant savings on energy costs and improved comfort for the building occupants.

In California, a homeowner installed spray foam insulation on their metal roof. The home was previously heated and cooled using a heat pump system. Following the installation, the home was able to reduce its energy consumption by 15%, leading to annual savings of approximately $1,000 on energy costs.

These examples highlight the tangible benefits of spray foam insulation in terms of energy efficiency and cost savings, making it an increasingly attractive choice for property owners seeking to optimize their energy usage and reduce their carbon footprint.

Maintenance and Regulatory Considerations

While spray foam insulation offers numerous advantages, it’s important to maintain it regularly to ensure optimal performance and longevity. The insulation should be inspected periodically for any signs of damage, such as cracks or leaks, and any issues should be addressed promptly to prevent moisture intrusion and other problems.

It’s worth noting that spray foam insulation is regulated by various building codes and safety standards. When choosing a contractor to install spray foam insulation, it’s crucial to select a professional who is experienced, qualified, and follows all applicable regulations. Spray foam insulation is a hazardous material, and its installation should only be undertaken by trained and certified professionals who adhere to strict safety protocols.

Comparing Spray Foam to Other Metal Roofing Insulation Options

While spray foam insulation has emerged as a standout choice for metal roofing, it’s valuable to compare it to other insulation options to better understand its unique advantages.

Batt insulation, a traditional insulation material made up of long fibers held together by a paper backing, is often installed between the roof decking and metal roof panels. However, this method can struggle to provide the same level of continuous coverage and airtight sealing as spray foam insulation.

Rigid board insulation, composed of extruded or expanded polystyrene, is another option that is typically installed over the roof decking and under the metal roof panels. While rigid boards offer reasonable insulation performance, they lack the seamless, conforming properties of spray foam, which can lead to gaps and potential areas of thermal bridging.

Reflective insulation, a thin material coated with a reflective layer, is sometimes used in metal roofing applications, installed under the roof decking or between the decking and the metal panels. While reflective insulation can help reduce radiant heat transfer, it does not offer the same comprehensive insulation and air-sealing benefits as spray foam.

When compared to these alternative insulation methods, spray foam insulation stands out for its superior energy efficiency, exceptional waterproofing capabilities, and enhanced structural integrity. The continuous, airtight barrier it creates, coupled with its ability to conform to any surface, makes it a highly effective and versatile solution for metal roofing systems.

Consulting with Experienced Roofing Professionals

As you consider the use of spray foam insulation for your metal roof, it’s crucial to work with a reputable and experienced roofing contractor who can guide you through the process and ensure the proper installation of this specialized insulation material.

At Roofers Midland, we have a team of certified professionals with extensive expertise in spray foam insulation. We can assess your specific needs, recommend the right type of spray foam, and oversee the installation process to ensure the longevity and optimal performance of your metal roofing system.

By partnering with an experienced contractor like Roofers Midland, you can have confidence in the quality of the materials used and the workmanship involved. We prioritize safety, adhere to industry regulations, and provide comprehensive warranty options to protect your investment.

Don’t leave the future of your metal roof to chance. Reach out to Roofers Midland today and let us guide you through the remarkable benefits of spray foam insulation, tailored to the unique climate and needs of your property.

Conclusion

As I reflect on the evolution of roofing materials and techniques, the rise of spray polyurethane foam insulation in metal roofing stands out as a true game-changer. This innovative solution addresses the unique challenges of metal roofing, providing unparalleled insulation, waterproofing, and structural integrity, all while delivering significant energy savings and enhancing the overall durability of the roofing system.

Whether you’re a homeowner, a commercial building owner, or a fellow roofing professional, the advantages of spray foam insulation are simply too compelling to ignore. By leveraging this transformative technology, you can not only safeguard your investment but also contribute to a more sustainable built environment, all while enjoying the benefits of enhanced comfort, reduced energy consumption, and long-lasting protection.

As you navigate the roofing landscape, I encourage you to explore the remarkable potential of spray foam insulation for your metal roofing needs. Consult with experienced professionals, weigh the long-term benefits, and make an informed decision that will serve your property and your energy-efficiency goals for years to come.

The future of roofing is here, and spray foam insulation is at the forefront of this exciting evolution. Join me in embracing this innovative solution and unlock the full potential of your metal roofing system.